US-01 - NF

Silicon Nozzle

Machines > Narrow Fabric Solution > US-01 - NF

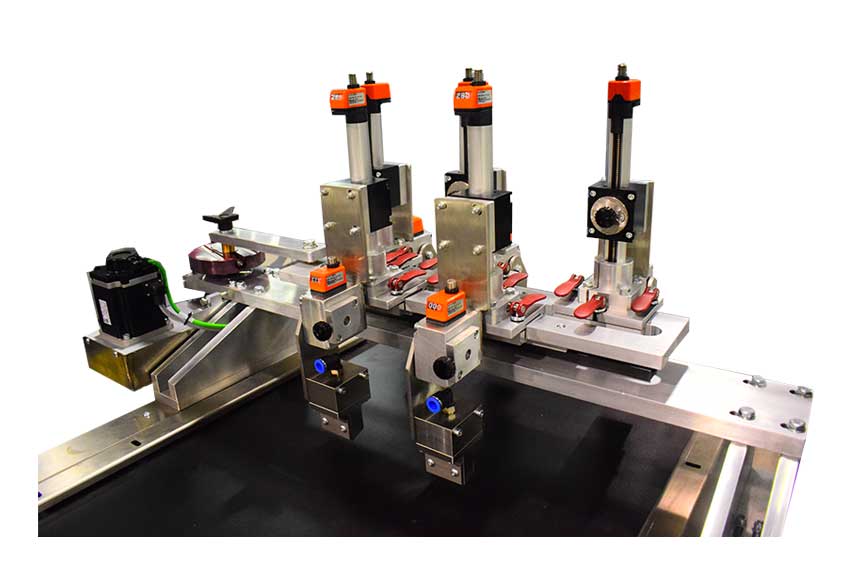

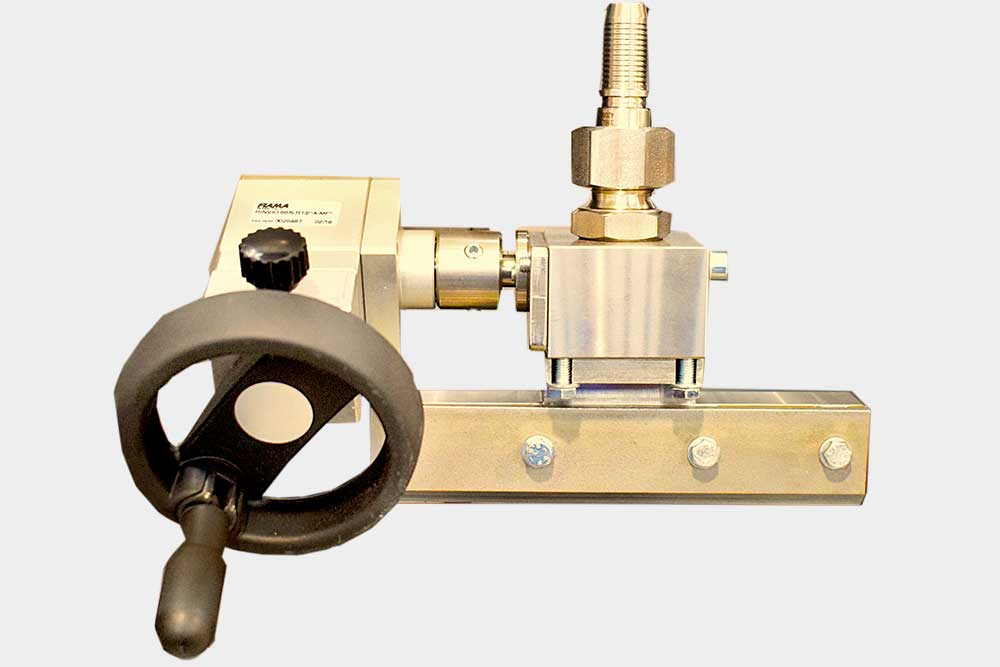

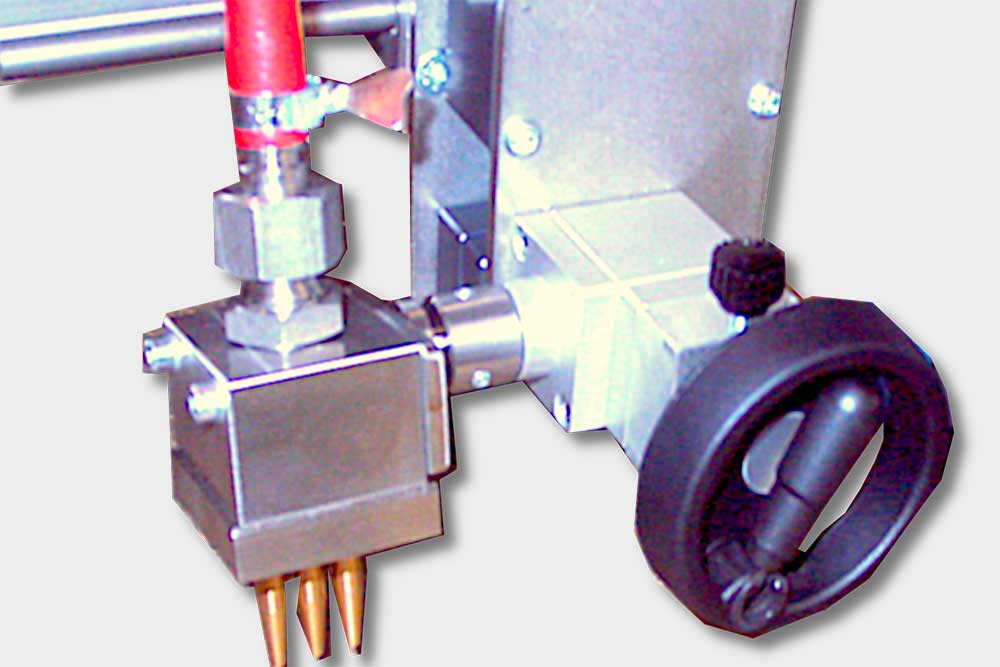

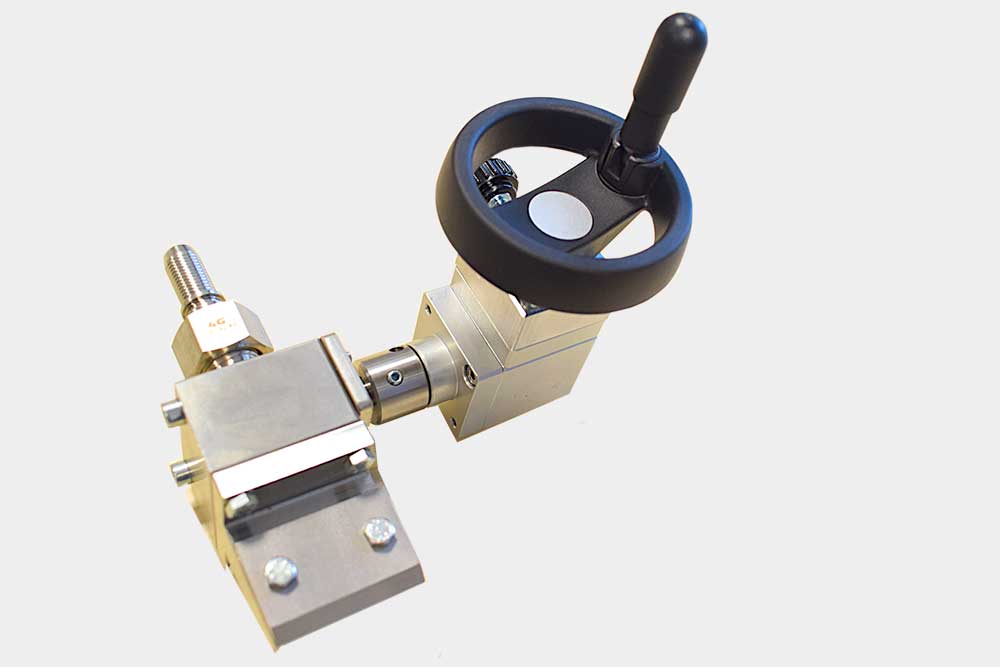

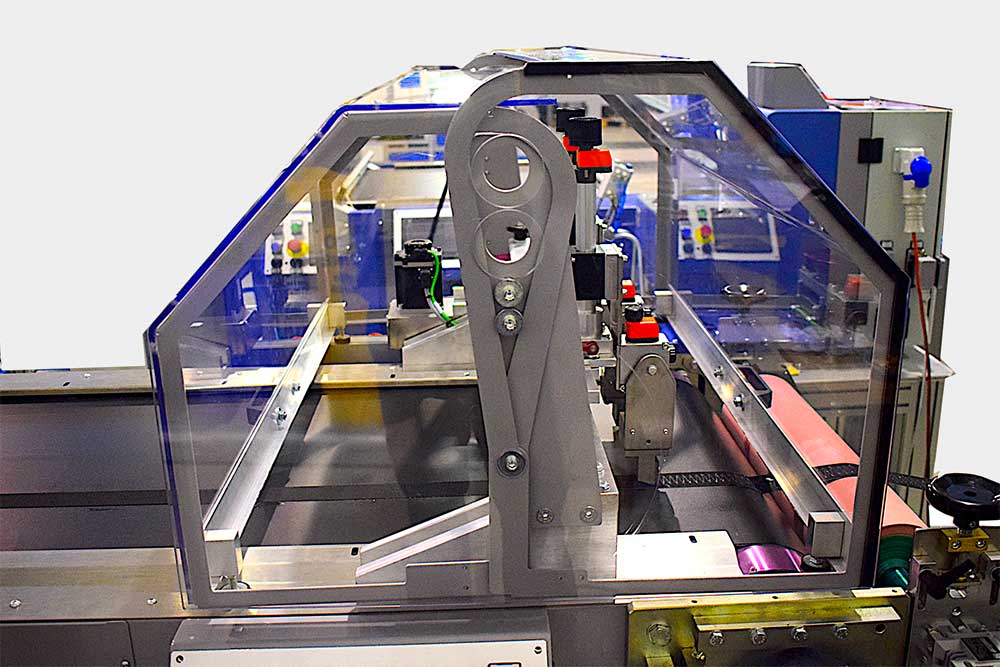

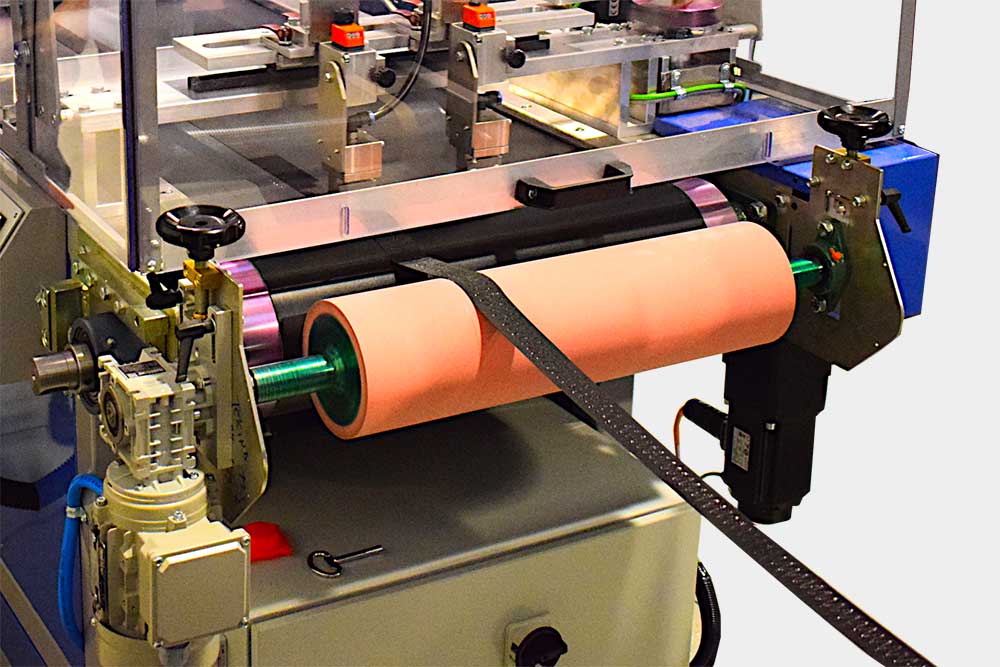

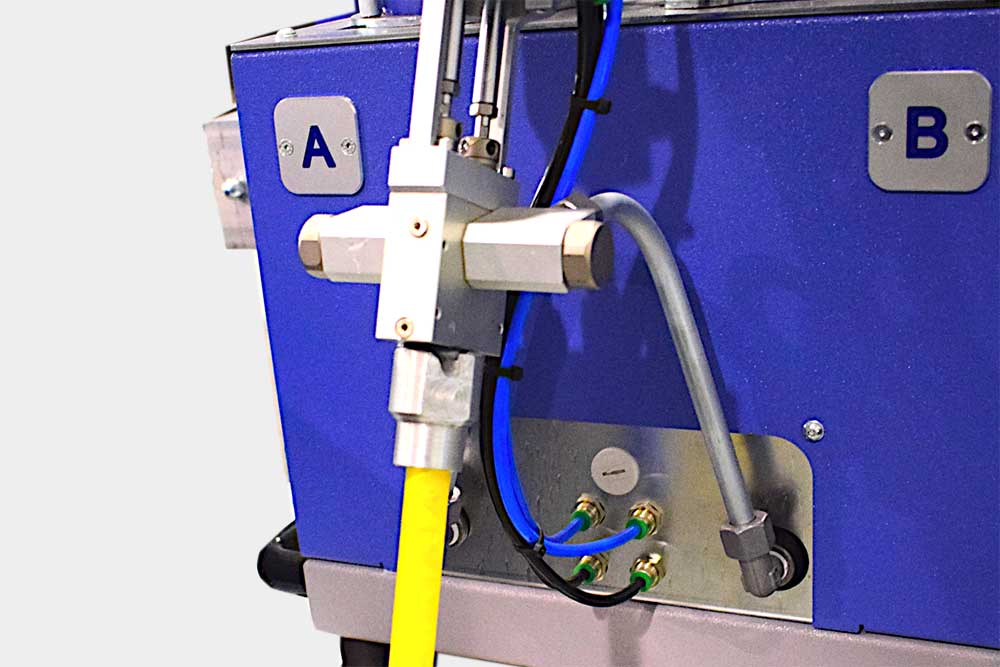

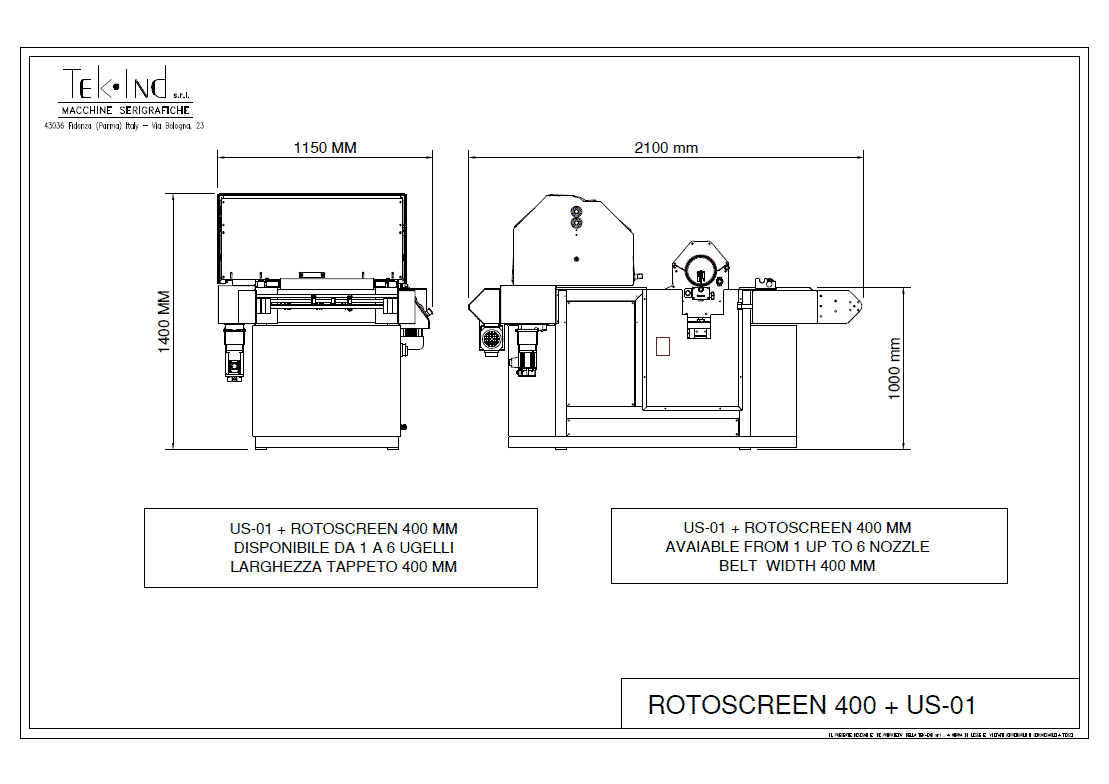

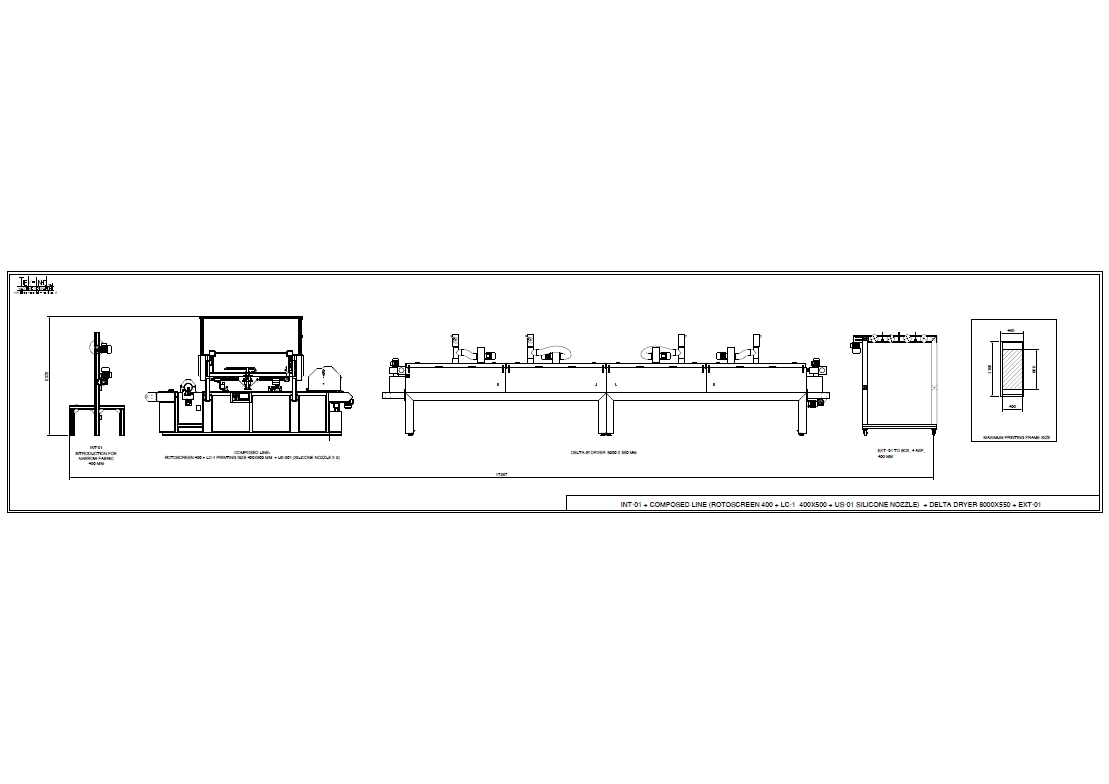

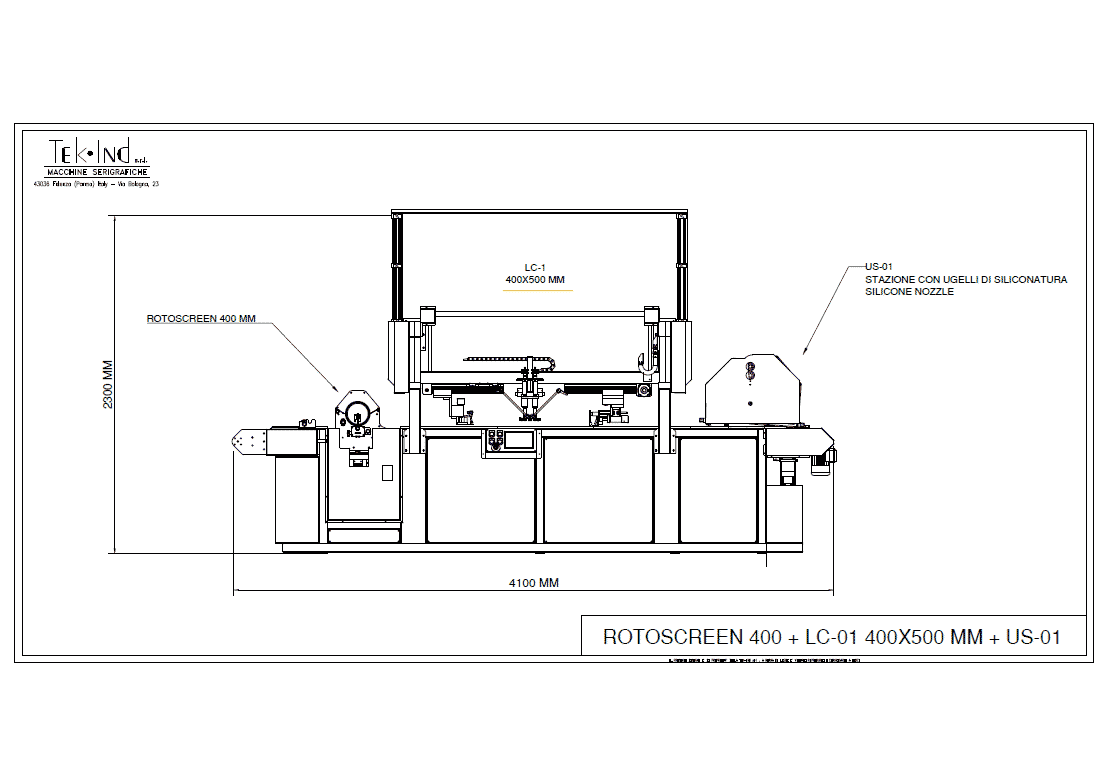

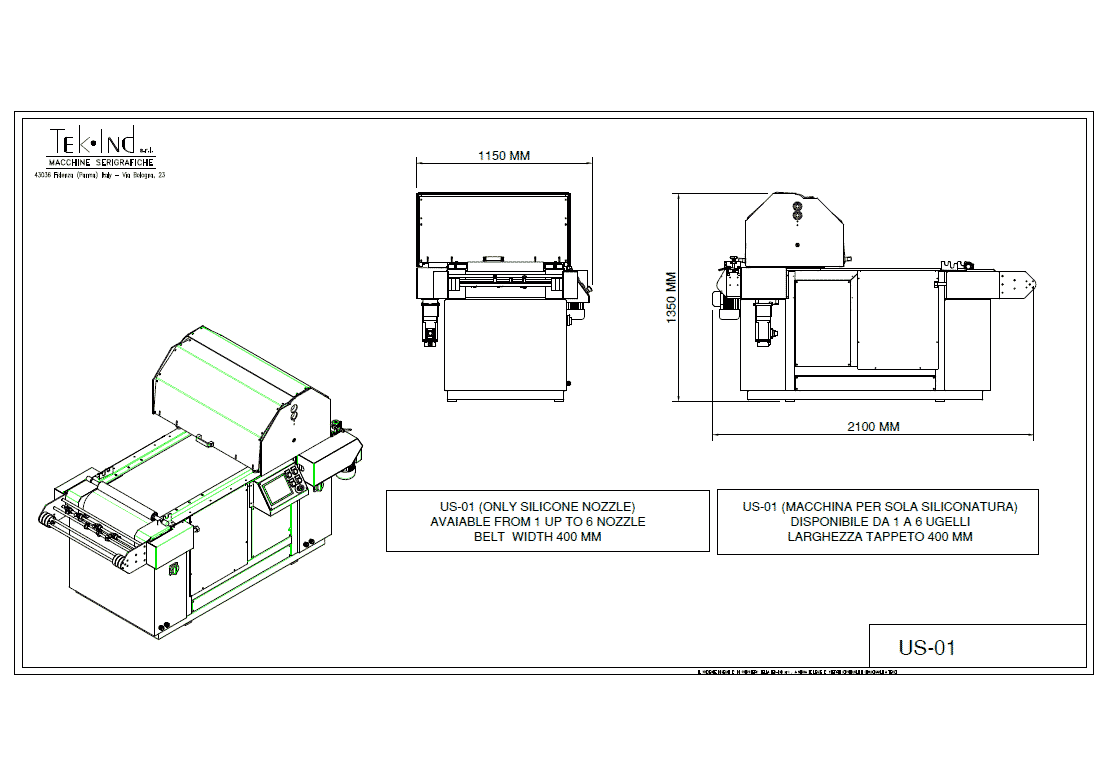

In order to carry out some types of printing such as strips and coatings for the entire length of the strip, the following equipment must be used: US-01; this equipment allows to make straight or wavy strips and flat spreads with variable thickness. US spreader can be combined with any line: Rotoscreen, LC, GA or possibly applied to an already existing coating line. The apparatus is as follows: loading of the bi-component silicone from two separate inlet points, silicone is then mixed using a spiral nozzle, which is replaced every time work is interrupted. The already mixed silicone is conveyed at this point to a nozzle through a tube for high pressures application, the nozzle can have different shapes depending on the strips it has to create. The main shape that we can distinguished are Nozzle dispenser: it has from a minimum of one to a maximum of three nozzles at a time, can be used for make strips (see Fig.A); and Blade dispenser: this type of nozzle allows creating coatings thanks to blade-shaped slots.

MAIN TECHNICAL FEATURES

- Types of nozzles Strips Nozzle; Coating nozzle

- Height adjustment from the belt 0 - 20 mm

- Wave height adjustment 0 - 30 mm

- Nozzle angle adjustment from the belt 0 - 90°

- Voltage 400V 50Hz 3F+N+T

- Consumpion 1,5 Kw

- Air Pressure no needed

- Dimension (L x W x H) 1.000 x 750 x 500 mm

- weight 25 kg

- Complementary equipment Bicomponent silicone gear pump (SP-20; SP-20C, SP-200)

- installable on: Rotoscreen, LC, GA and existing coating lines