Gamma Wood

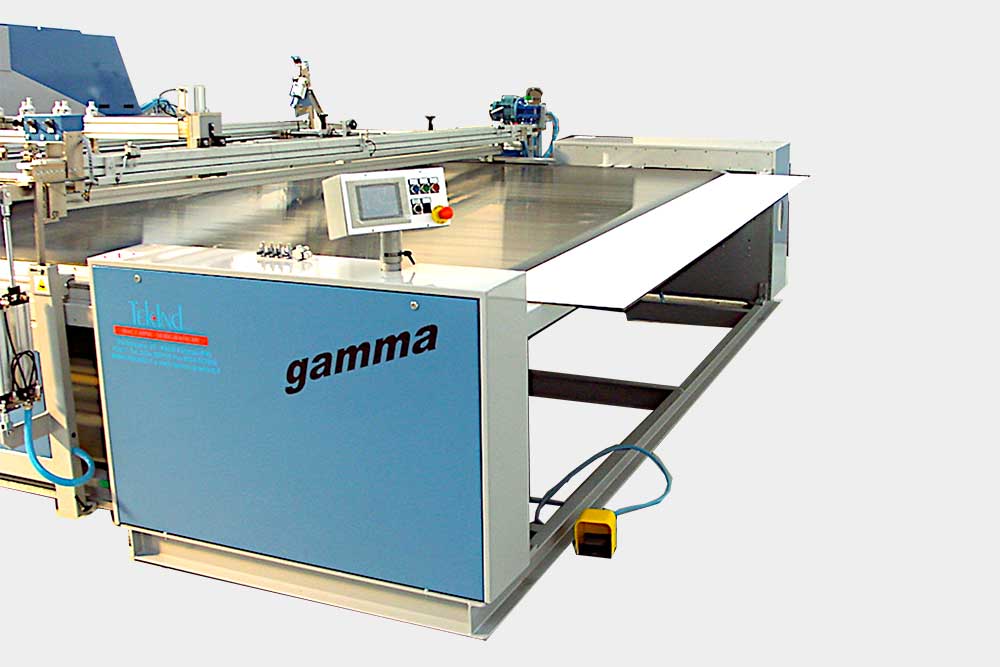

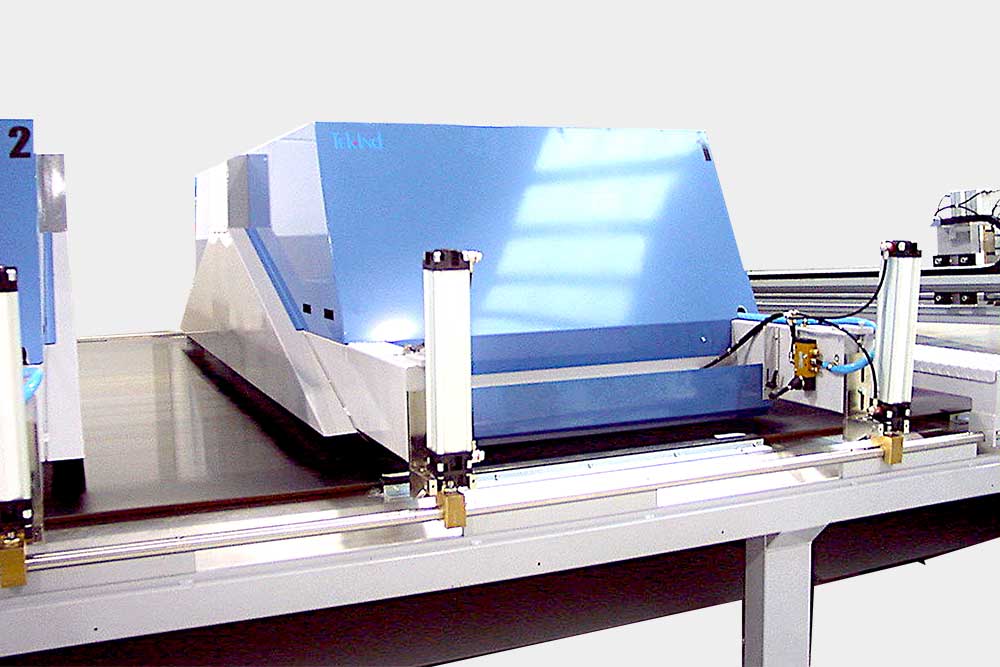

Flat check printing machine

Macchine > Graphics > Gamma Wood

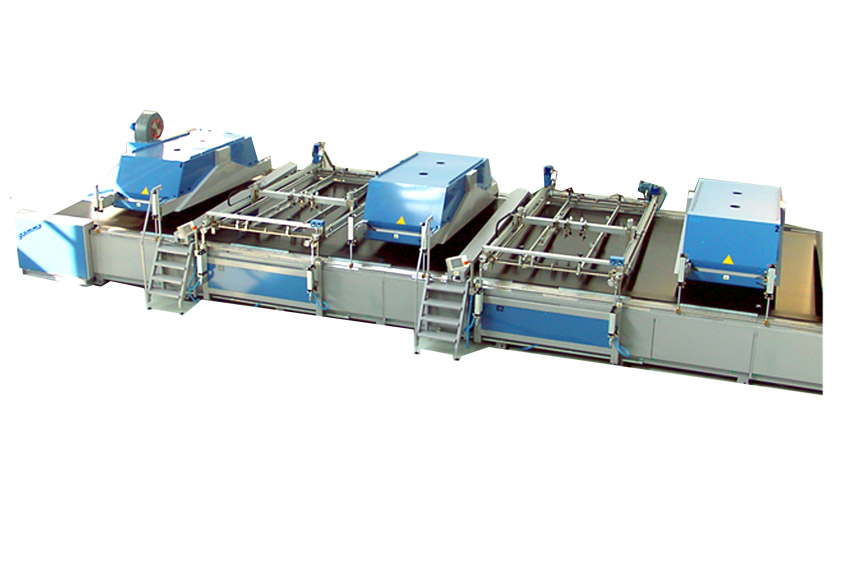

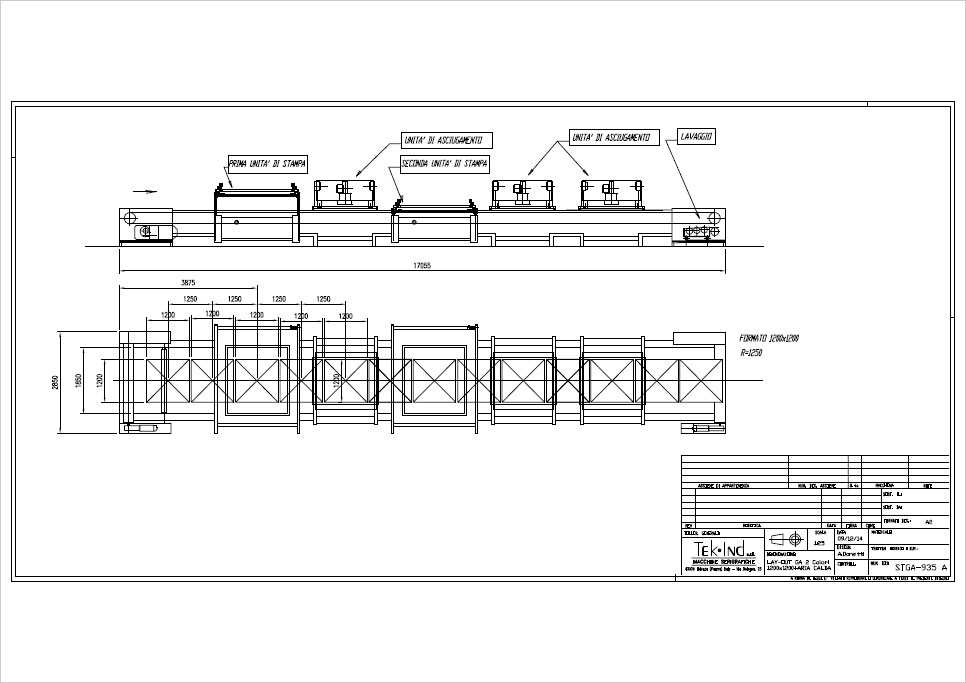

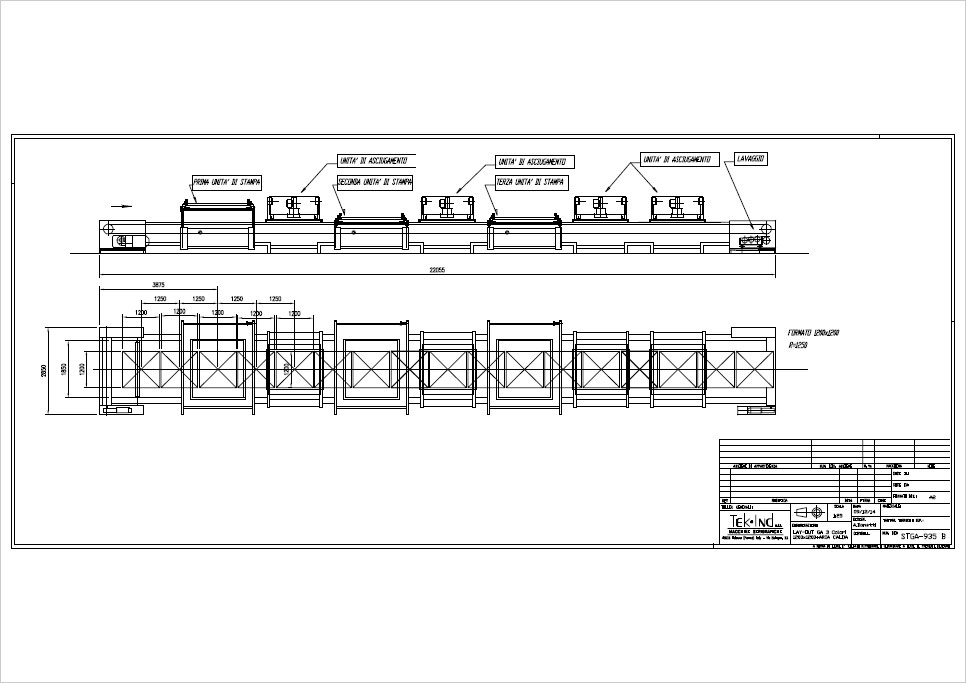

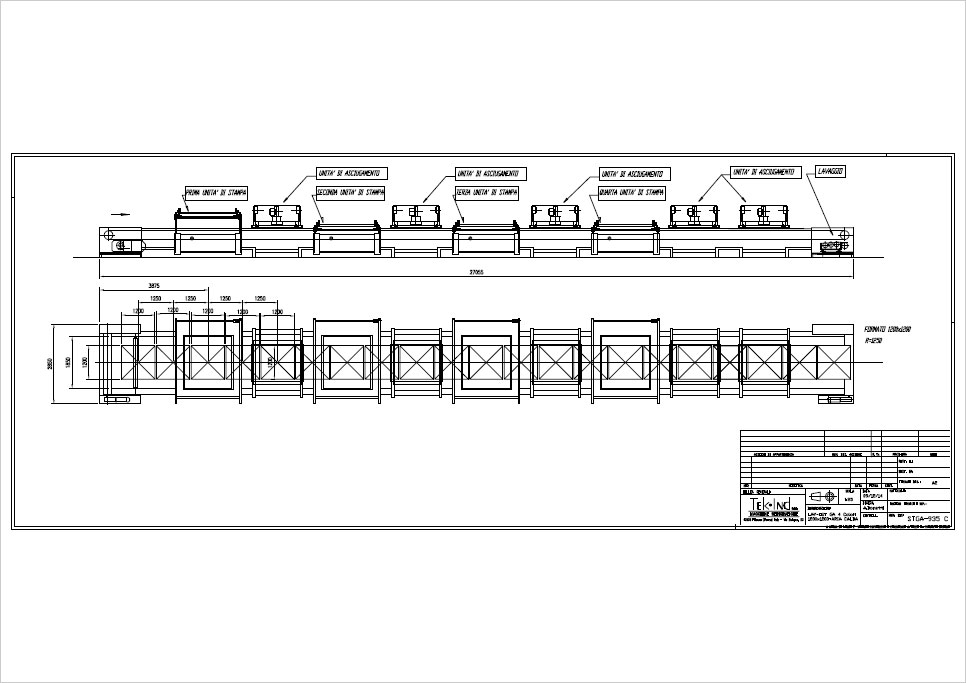

Multi-color screen printing machine for wood printing application, in this version gamma machine has three printing units each interspersed with special intermediate drying hoods, after the first color / treatment there is also a cooling hood, for cooling the printed surface. The transport of the panels is carried out using a printing belt, which guarantees high positioning precision and good resistance to loads. Gamma Wood can make prints up to a maximum of 280x120 cm and support panels up to a maximum of 150x300 cm and having a total weight not exceeding 600 kg, for an average stroke length of 225 cm the theoretical production is 6 pieces / min. Loading and unloading can be integrated through special systems made according to the material to be handled.

MAIN TECHNICAL FEATURES

- print format: 120 x 280 cm

- maximum panel size: 150 x 300 cm

- number of printing units: 3

- number of intermediate drying hoods: 3

- number of cooling hoods: 1

- maximum print support thickness: 0 - 30 mm

- total length of the machine: 19 m

- total machine width: 4.7 m

- worktop height: 85 cm.

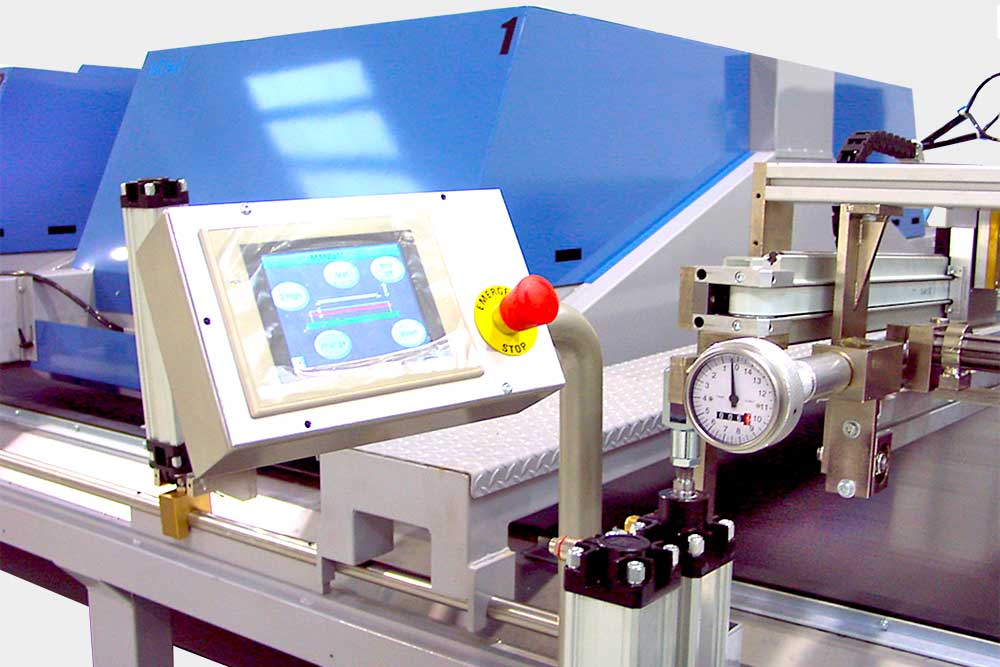

- Print ratio accuracy: +/- 0.25 mm.

- squeegee speed: 0-40 mt./min.

- Theoretical vacuum printing R = 2250: 6 pieces / min.

- Installed electric power: about KW 150

Gamma wood range features in detail

ADHESIVE FILM DRAWING UP

For the laying of permanent adhesives, a squeegees will be placed at the entrance, the same, mounted on special guides, can be removed once the drawing up operation is complete.

BELT CLEANING DEVICE

Positioned underneath the outlet section of the machine, it is composed of:

- Stainless steel tank properly sealed.

- Three electrically driven rotary brushes.

- After-cleaning twin squeegee to remove the water from the belt.

- Pneumatic device for lifting.

CARPET PRE-HEATING HOOD

Carpet pre-heating hood: Placed in the lower part of the carpet at the machine input it will have the function of heating the thermoplastic adhesives previously spread on the printing ribbon. This will allow to obtain the desired tack value in relation to the supports to be treated.

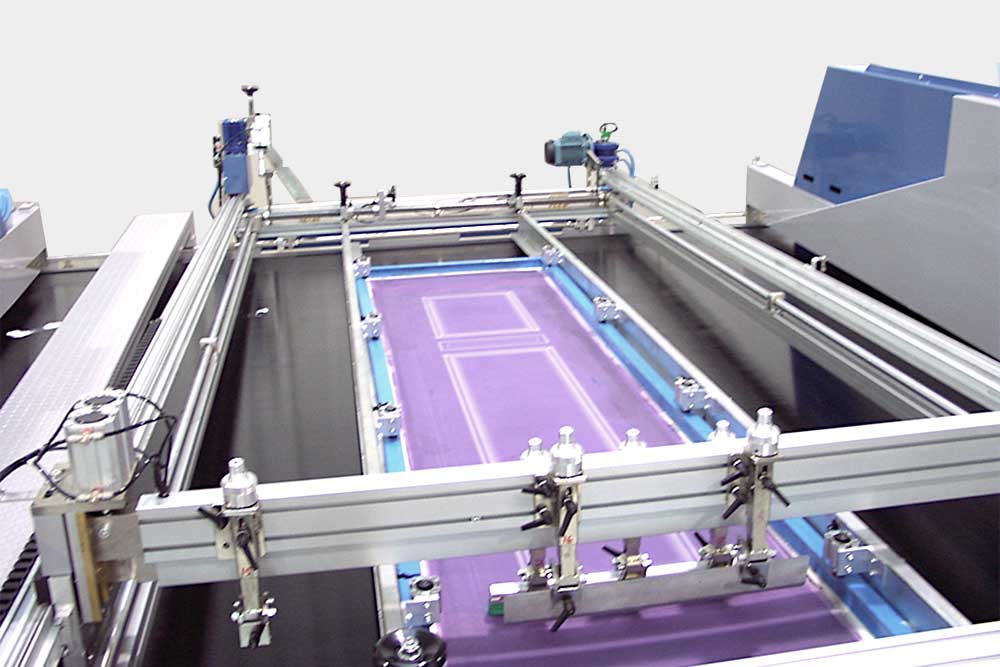

PRINTING UNITS

N° 3 printing units featuring an independent open structure composed of:

- Squeegee speed linearly variable from 0 to 40 m/min.

- Pneumatic squeegee/flood bar inversion.

- N° 2 pressure adjustment sliding on the squeegee/flood bar holding group

- Possibility to modify the squeegee/flood bar working angle

- Possibility to modify the squeegee obliquity compared to the sliding axis of the squeegee holding groups.

- Pneumatic cleaning lifting (50 cm)

- Transversal and longitudinal centring registers of the drawing.

- Squeegee stroke independently adjustable on each printing unit by encoder.

- squeegee manual test

- screen up and down selector

- start and stop buttons

- selector for maxim lift for cleaning

- squeegee speed pre-selector

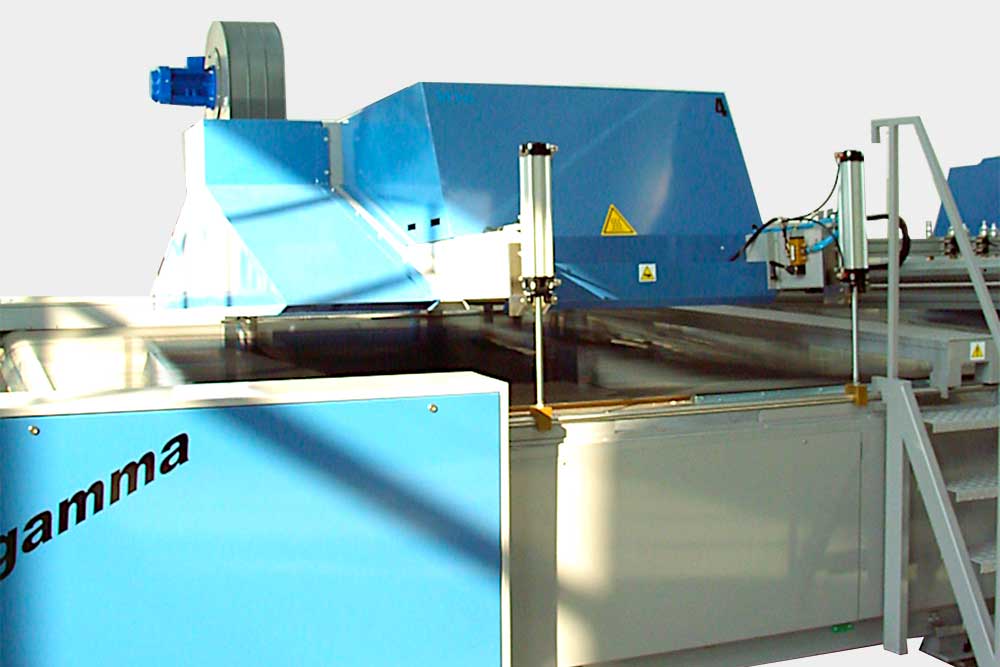

HOT AIR HOODS

N° 4 air dryers providing the ink curing between each printing unit. They are composed by:

- n° 3 electro-fans featuring a max. capacity of 600 mt3/hour each.

- blowing area equipped with holes (whose number and location, together with the distance from the support, ensure a perfect working uniformity)

- n° 2 lateral chambers for the air recirculation

- n° 2 pneumatic cylinders for the horizontal lifting of the whole hood. This function allows the accuracy control between each colour

- n° 2 resistance batteries of KW (to be notified according to the technical tests to be carried out)

- each blower is completely independent and power supplied by the printing machine. It can slide on guides along the machine.

- useful blowing area: 120 x 280 cm.

COOLING HOOD

Cooling hood manufactured in steel and placed after the final hot air blower, equipped with:

- n° 1 electro-fan having a capacity of 600 mt.3/hour

- blowing area equipped with holes (whose number and location, together with the distance from the support, ensure a perfect working uniformity)