Gamma Textile

Square screen printing line for fabrics

Machines > Textile > Gamma Textile

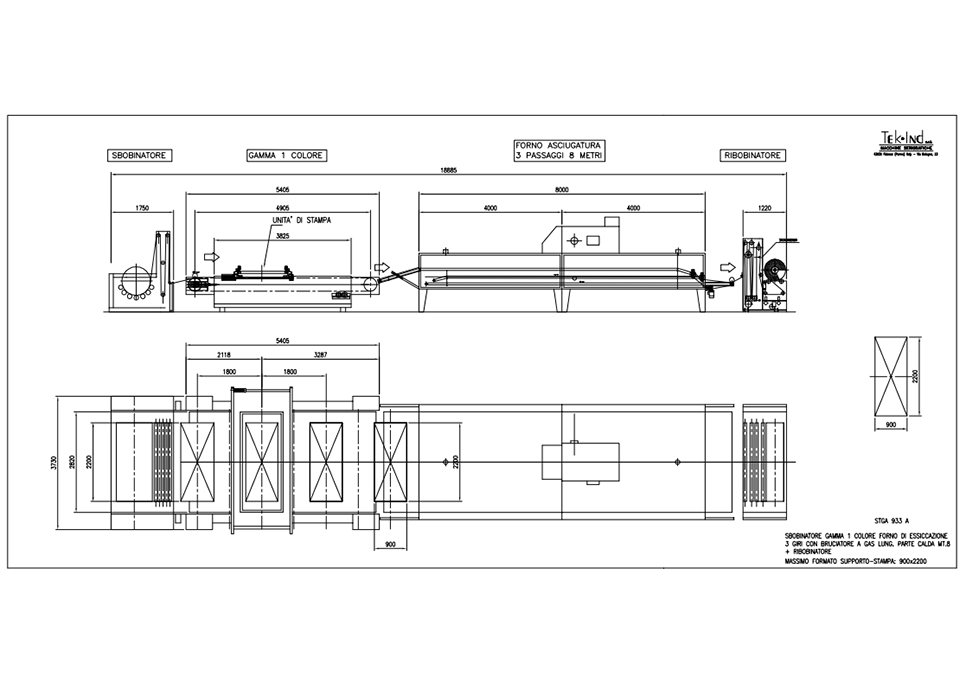

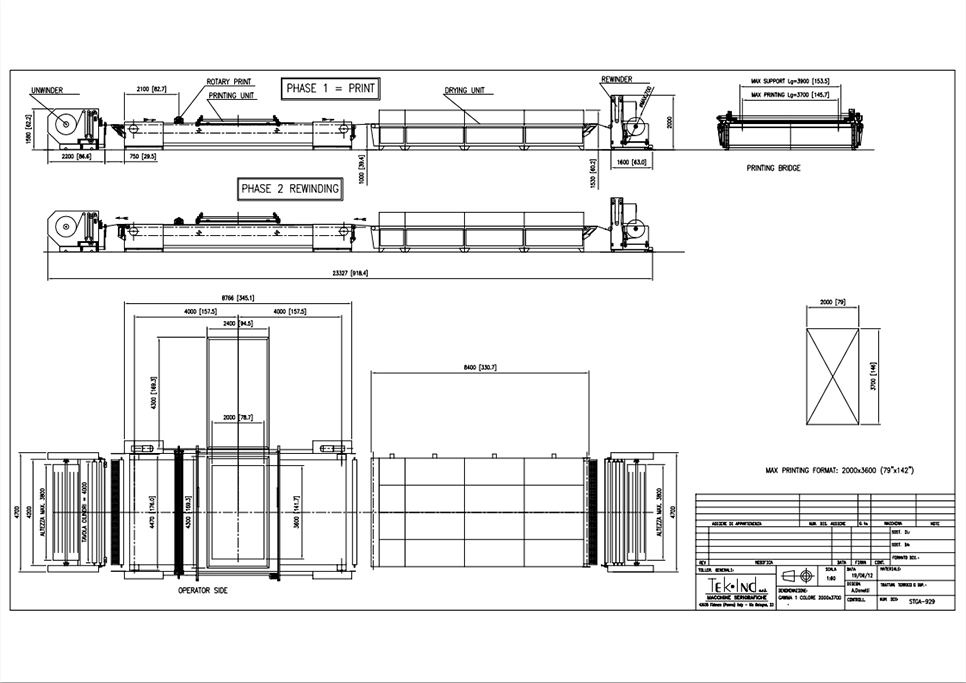

Screen printing line for continuous fabrics, with number of printing units that can be customized according to customer requests, the printing line is structured as follows:

• INT-01 TX - introductions for fabrics

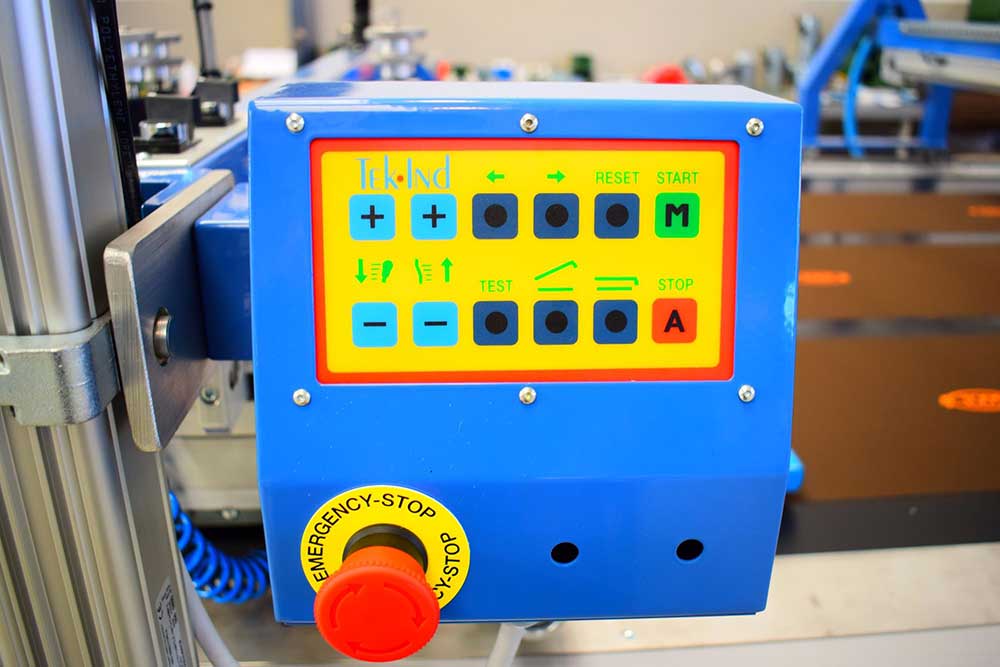

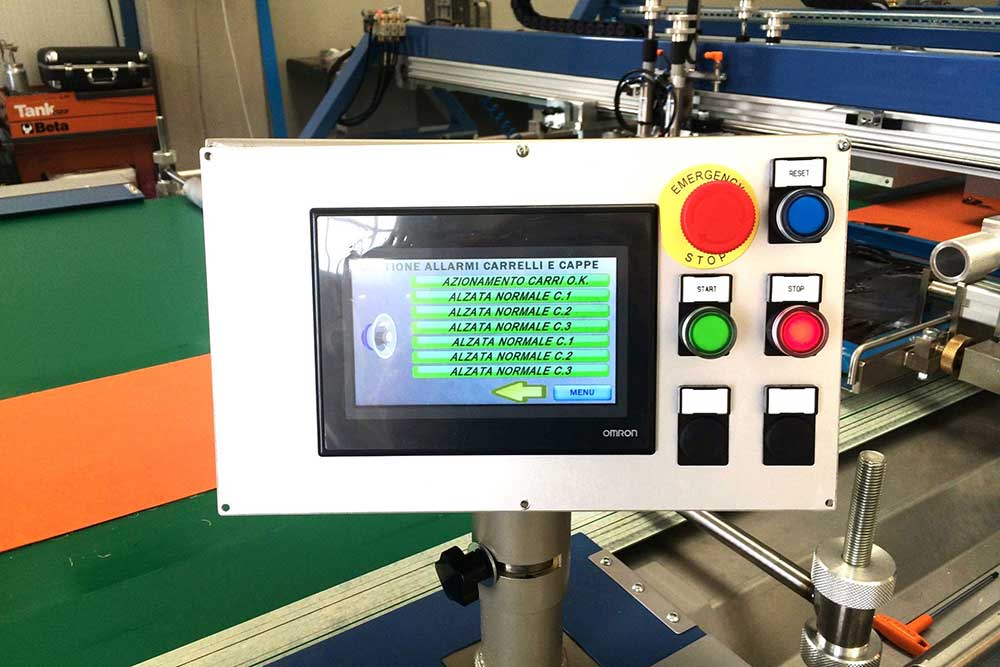

• Gamma-TX - flat silk screen printing machine from 1 to 12 printing unit

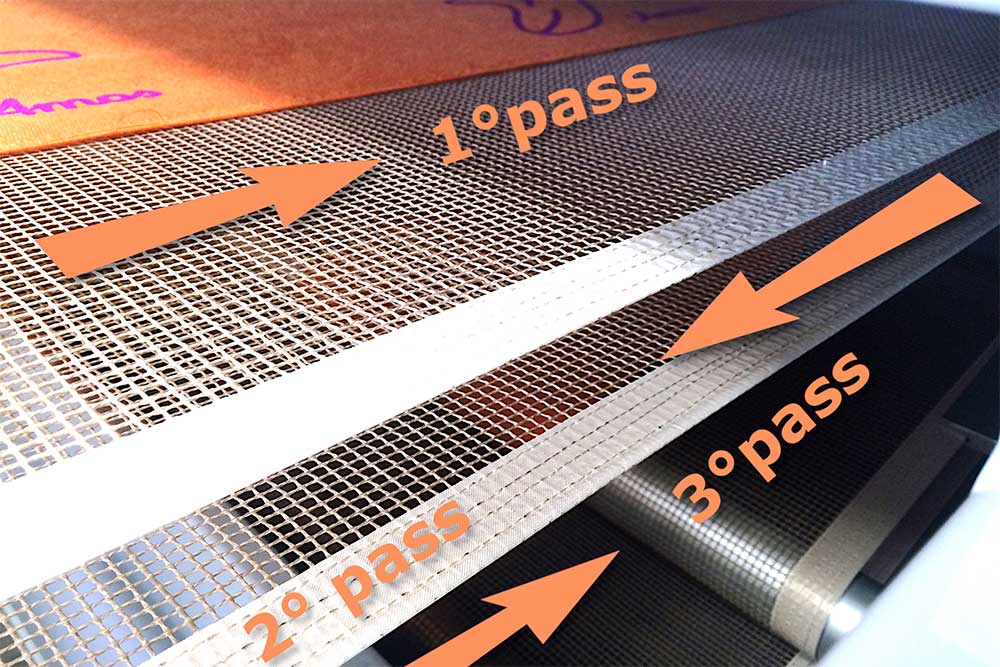

• Ghibly 3P-TX - three pass drying oven

• EXT-01 TX – rewinder for fabrics

• INT-01 TX - introductions for fabrics

• Gamma-TX - flat silk screen printing machine from 1 to 12 printing unit

• Ghibly 3P-TX - three pass drying oven

• EXT-01 TX – rewinder for fabrics

MAIN TECHNICAL FEATURES

- Fabric unwinder can manage one reel at a time, the fabric after being unwound is folded to remove any tension on the fabric to be printed.

- The unwinder feed the printing line, a photocell controll the correct unwinder speed.

- The printing belt is drived by a servo motor that allow the correct printing posictioning.

- A glue layer that cover the printing belt give adesion to the fabric.

- Printing unit: 1 to 12 printing units

- Stroke lenght, squeges inclination, pressure and number of passes can be adjust

- Print format: 90x180 cm (other on customer request)

- Possibility to mount frames of different sizes up to the maximum size managed by the machine.

- maximum fabric reel width: 200 cm

- Type of usable fabric : elastic fabric (Ex: jersey fabric) Rigid fabrics (no woven fabrics)

- Integrated carpet washing system

- Ghibly oven with three passages: this 6 m total length oven allows to triple the time of permanence of the fabric in the oven, the fabric after a first passage is sent back thus giving the possibility to lower the drying temperature and in any case to dry the prints without damaging the fabric.

- Possible power supply for the oven: Gas, LPG, Diesel, Electric.

- EXT-01-TX: the line ends by rewinding the reels, special laser systems allow that the reels is rewound straight.

- Total line length: 28.3 m (ex: 8 printing units)

- Total line width: 320 cm

- Worktop height: 91 cm

- Theoretical production: 10-12 cycles / min

- Print ratio accuracy: +/- 0.2 mm.

- Electric power installed:

- INT-01-TX: 3 Kw

- GA-3 colors + 2 IR hoods 40x2: 29 Kw

- Ghbly 2,5 Kw + 90.000 Kcal

- EXT-01 TX: 3 Kw

- Totale: 38 Kw + 90.000 Kcal

Characteristics of Gamma Textile in Detail

Line configuration

The line will be configured as follows:

- unwinding

- 8 printing units

- N ° 1 Ghibli T3-9-200 Diesel dryer

- Ribobinataore

INT-01 TX

- Introduction dimensions Length: 210 cm

- Introduction dimensions Width: 265 cm

- Dimensions introduction Height: 220 cm

- Max. roll width: 200 cm

- Max. roll diameter: 80 cm

- Max. roll weight: 300 kg;

- Machine speed: 25 mt./min.

- Max. hourly production: 1500 m / h

MOTORIZED TAKE UP CRADLE

Device made with two cylinders covered with rubberized tape, one of which is motorized by gearmotor and Inverter to obtain optimal acceleration and stop ramps for unwinding large rolls.

PHOTOCELL STOP FOR LACK OF FABRIC

Stops the unwinding cradle and the motorized upper cylinder due to lack of fabric on the unwinding area, leaving a supply of fabric sufficient for sewing the next roll.

MOTORIZED UPPER CYLINDER

Cylinder covered with rubberised belt, motorized by a fixed speed gearmotor used for loading the J. Box.

FLAP CREATION DEVICE

Oscillating group necessary for the creation of fabric layers during the loading phase in the J. Box.

J. BOX GROUP

Stainless steel cradle used for the accumulation of the fabric to obtain a sufficient supply for the loading and sewing of the new rolls.

BRAKE CYLINDER TENSIONING FABRIC

Idle cylinder covered with synthetic velvet ribbon. The fabric that will be pulled by the printing machine is adequately tensioned.

ELECTRO-PNEUMATIC CENTERING DEVICE

Made with a triad of coated coated cylinders. Fixed on oscillating levers that allow an electro-pneumatically controlled transversal movement and controlled by optical sensors that guarantee correct alignment with the printing line.

Drawing up of adhesive film

For the laying of permanent adhesives, a doctor blade is placed at the entrance, the same, mounted on special guides, can be removed once the gluing operation is finished.

Water soluble glue tank

Tank for the containment of water-soluble glue located at the machine inlet equipped with an idle roller for transferring the glue onto the printing ribbon and a WKL doctor blade for accurate adjustment of the thickness of the adhesive.

Print unit

On the installed printing units it is possible to carry out the following adjustments: squeegee speed and color recovery, pressure adjustments on the squeegee and scraper unit, squeegee and scraper inclination adjustment, out of automatic contact, unilateral pneumatic lift at a height of 50 cm for frame cleaning operations . Print carriage stroke adjustment by end of stroke. Each printing unit has centering registers that guarantee the perfect centering of all colors used in the printing phase.

Carpet Cleaning System

Press carpet cleaning tank made up of stainless steel tank, inside which there are three rotating brushes, after the tank two rubber spatulas remove excess water still on the carpet, the tank can be raised and lowered by means of a pneumatic lift, and also extracted for cleaning.

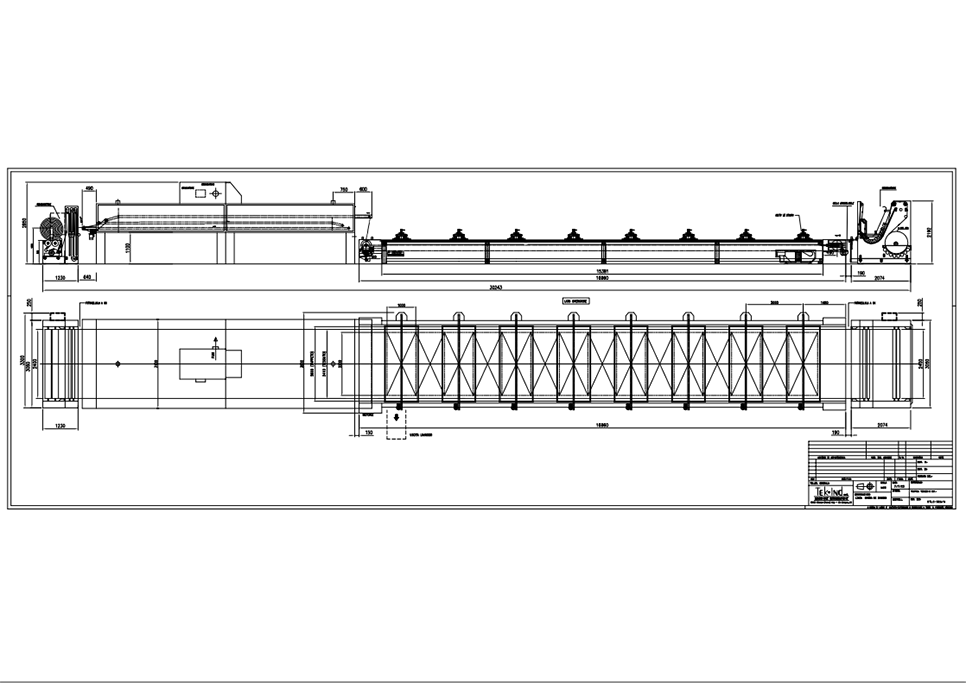

Ghibly 3P-TX

Ghibly oven with three passages: this oven with a total length of 6 m / 9 m allows to triple the residence time of the fabric in the oven, after a first passage the fabric is sent back thus giving the possibility to lower the drying temperature and succeed in any case, to dry sufficiently the print made without damaging the fabric. Possible power supply for the oven: Gas, LPG, Diesel, Electricity.

Techine specifications "GHIBLY T3-9-200"

Techine specifications "GHIBLY T3-9-200"

- Useful drying field: 900 x 200 cm

- Teflon glass carpet width: 200 cm

- Number of carpets: 3

- Maximum allowable temperature: 180 ° C

- N ° 1 electric fan of 3.500 mt.3 / hour

- N ° 1 exhauster for air exchange

- insulation along the entire length of the oven

- Installed thermal power: 200,000 Kcal.

- Installed electrical power: 5 KW.

- Independent belt speed: from 1.3 to 6.3 m / min.

EXT-01 TX

The line ends by rewinding the bobbin, special laser systems ensure that the bobbin is rewound straight, below the technical specifications of the EXT-01 TX fabric winder.

DANCER GROUP WITH FREE CYLINDERS

Made from support plates with ball circulation sliding unit with balancing system through mechanically connected counterweights, to recover a sufficient amount of fabric to allow the operator to unload the newly formed roll and restart the formation of the next one without having to stop the printing machines.

ELECTRO-PNEUMATIC CENTERING DEVICE

Made with a triad of coated coated cylinders. Fixed on oscillating levers that allow an electro-pneumatically controlled transversal movement and controlled by optical sensors that guarantee correct alignment with the roll being formed.

CROLLER GROUP COILER

Device made with two coated cylinders, one of which is motorized directly by means of a gearmotor and inverter to obtain optimal acceleration ramps for rolling large rolls and adjusting the speed set by the potentiometer on the dancer unit. The second winding cylinder controlled by a mechanical variator unit rotates at an adjustable speed slightly higher than that of the first cylinder, to guarantee a slight tension of the fabric necessary to obtain a roll of adequate consistency.

PNEUMATIC BRAKE GROUP

Made with a rubberized crossbar operated by pneumatic cylinders, controlled directly by a manual selector. It is used to hold the fabric during the unloading operations of the roll and keep it in tension in the dancer group

- Length: 125 cm

- Width: 265 cm

- Height: 220 cm

- Max. roll width: 200 cm

- Max. roll diameter: 80 cm

- Max. roll weight: 300 kg;

- Machine speed: 25 mt./min.

- Max. hourly production: 1500 m

DANCER GROUP WITH FREE CYLINDERS

Made from support plates with ball circulation sliding unit with balancing system through mechanically connected counterweights, to recover a sufficient amount of fabric to allow the operator to unload the newly formed roll and restart the formation of the next one without having to stop the printing machines.

ELECTRO-PNEUMATIC CENTERING DEVICE

Made with a triad of coated coated cylinders. Fixed on oscillating levers that allow an electro-pneumatically controlled transversal movement and controlled by optical sensors that guarantee correct alignment with the roll being formed.

CROLLER GROUP COILER

Device made with two coated cylinders, one of which is motorized directly by means of a gearmotor and inverter to obtain optimal acceleration ramps for rolling large rolls and adjusting the speed set by the potentiometer on the dancer unit. The second winding cylinder controlled by a mechanical variator unit rotates at an adjustable speed slightly higher than that of the first cylinder, to guarantee a slight tension of the fabric necessary to obtain a roll of adequate consistency.

PNEUMATIC BRAKE GROUP

Made with a rubberized crossbar operated by pneumatic cylinders, controlled directly by a manual selector. It is used to hold the fabric during the unloading operations of the roll and keep it in tension in the dancer group